Cutting Thickness 50mm Concrete Dosing Machine Automatic For Stone Crushing

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | USD |

| Packaging Details: | Normally carton box or following customer's requirements for Artificial stone production concrete brick making machine line on sale. |

| Delivery Time: | 15Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Place Of Origin: | Henan, China | Size: | 1500*1300*2500cm |

|---|---|---|---|

| Filling Material: | Cement Concrete | Function: | Producing Artificial Stone |

| Material: | Steel | Stone Form: | Wall Brick |

| Highlight: | Cutting t50mm Concrete Dosing Machine,Stone Crushing Concrete Dosing Machine,automatic Concrete Dosing Machine |

||

Product Description

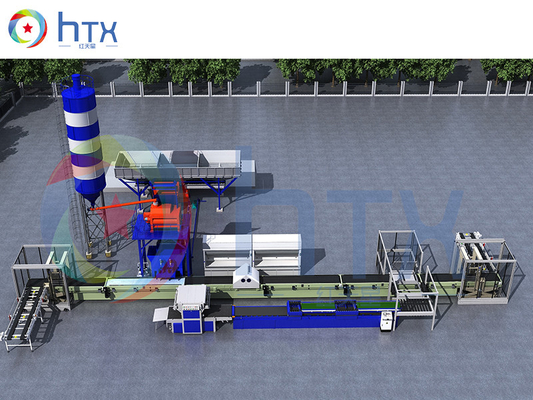

Cutting thickness 50mm automatic concrete material volumetric doser for stone crushing production line

This equipment is a cultural stone production line designed, produced and processed by our company.

1. The equipment has the characteristics of timing cutting and timing vibration. Workers are easy to operate, easy to use and fast, with high work efficiency, and the shift output can reach 800 square meters.

2. Our factory integrates the production of cultural stone mold forming machine, cultural stone production line equipment and various cultural stone molds. Introduce new foreign technology and independently develop unique new formulas.

3. Purchase production equipment and large mold products, receive free training in artificial stone production and color matching technology, and guide the manufacturing technology of artificial stone molds to train the production and color matching process of artificial cultural stones!

Characteristic:

Veneer stone production line,is designed for concrete pavers making through plastic molds,and surposed to improve the capacity of the production,and just 4-5 workers needed in the whole production line,only below 7.5kw power consumption,it will be a cost effective choice for pavers producing.Also,this machine can feed concrete automatically,and can fix the accurate concrete feeding by a pneumatic controller,can vibration automatically,can transport molds automatically,it is the better choice compare with the vibration table only both cost and efficiency.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

| Artificial stone production line | HTX-P-01a | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1kw | 800-1000 | 2000 |

![]()

![]()

![]()

Product Feature:

1. Low tolerance of bricks manufactured, with good uniformityIt adopts computer operation, advanced control system and low noise, eliminating the need for indoor and outdoor construction and decorative plaster.

2. Materials are even inside bricks.The feeding of all raw materials is automatically controlled, which reduces the tolerance of the finished bricks. As long as the mold is changed, a machine for multi-purpose finished bricks can be manufactured.

3. Eliminating the need for interior and exterior architectural and decorative stucco.High level of automation and intelligence, cost saving, standard and beautiful appearance of finished products

4. Improve the grade of bricks, the added value of products and the market coverage of bricks.

Application:

Artificial Stone has become an appreciated artwork to some extent. Types of brick face for natural-like series are imitated slad, imitated sandstone, imitated serpeggiante, etc.

An obvious trend of building development is the increasing attention to the external decorative artistry and internal culture appeal.To follow this trend, more and more buildings and decorative materials consciously or unconsciously stepped the culture and art. Thus, the combination of building brick and culture brick appears. The artsimulation process is added on the surface of the new generation decorative brick. No matter the natural-like, antique looking, or west architecture imitating , they are all lifelike.

![]()

![]()

![]()

FAQ:

1. What does the production line contain?

Include Mixer, Automatic production line, Drying rack,Forklift.

2. How do we debug the installation?

We will prepare a detailed installation instructions, and provide a complete installation video

3. How many people in the production line can operate normally?

A total of need 4-5 people ,1 spray color, 1 person placed the mold, 1trimming filler, 1-2 1 palletizing. shift production is 800-100m2

4. What are the advantages of our production line?

Timing vibration and Timing feeding ,automatic production line.