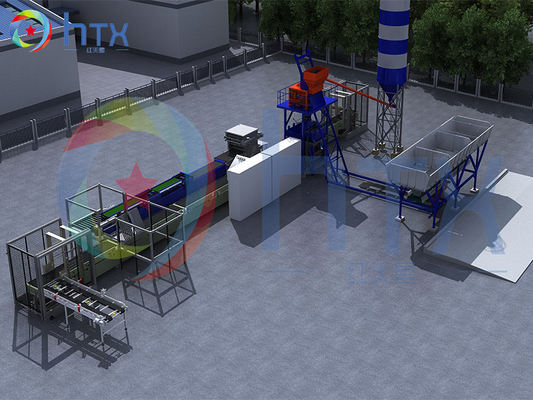

Concrete Retaining Block Feeding Machine Dosing System Manufacturers Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Product Name: | Concrete Precast Machine Line | Material: | Steel |

|---|---|---|---|

| Advantage: | Multi Function Wet Casting Doser Machine Production Line | Usage: | Construction |

| Voltage: | 220V | Size: | 1500*1300*2500cm |

| Highlight: | Dosing System Concrete Paver Making Machine,220V Concrete Retaining Block Feeding Machine |

||

Product Description

Concrete Retaining Block Feeding Machine Dosing System Manufacturers Production Line

Product Description

Cultured stone making feeding machine equipment for customers to save labor costs, reduce labor, and achieve automation and high-efficiency production. paving artificial stone production line making machine is divided into 15 parts from ingredients to packaging, which are connected and operated through a programmable control cabinet, each part and half part can work independently.All the parts include cement silo, batching machine,Auto Concrete forced Mixer,auto unloading machine , auto pallet turning machine,Auto Spray Machine,concrete filling machine,auto stacking machine,auto packing machine,auto demoulding machine,auto vibration part,Hydraulic conveyor,Air compressor,auto screen controller ,dust collecting machine. Concrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

![]()