House Exterior Cultured Concrete Wall Panel Machine Automatic Wet Doser

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Natural Manufactured Artificial Stone Production Line | Raw Material: | Conrete |

|---|---|---|---|

| Size: | 7000*1000*1800 | Material: | Steel |

| Feature: | High Productivity | Key Selling Points: | Easy To Operate |

| Highlight: | Automatic Concrete Doser Machine,Cultured Concrete Wall Panel Machine,12.7 Kw Concrete Wall Panel Machine |

||

Product Description

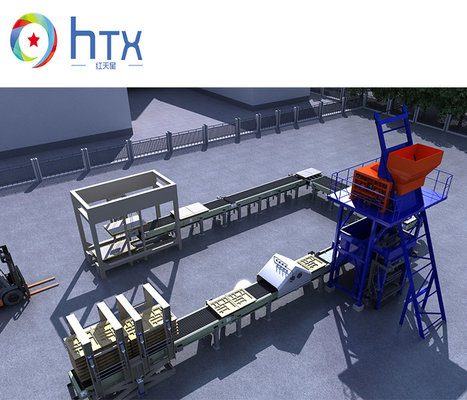

Automatic Cultured Stone House Exterior Production Line Wet Concrete Doser Machine

With the full auto artificial stone production line, the veneer stone manufacturer can save a lot of labor cost and can Increase productivity. More over, it can achieve collect dust in the workplace to protect environment, and also can demold automatically, this is a new progress during veneer stone production.

wet casting doser machine Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

Turning over the pallet with molds by 180C,place the molds and catch back the empty pallet to the main hydraulic conveyor.

· Hydraulic(turning) +Pneumatic (pallet&molds control)

· Pallet turning speed is adjustable(frequency motor controller)

· With transport roller conveyor for shipping the molds to the demolding machine

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

![]()

![]()

![]()