Automatic Concrete Dosing Machine 12.7KW Artificial Stone Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | USD |

| Packaging Details: | Normally carton box or following customer's requirements for Artificial Stone Concrete Dosing Machine Wet Casting Doser Machine. |

| Delivery Time: | 15Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Power: | 12.7 KW | Function: | Long Service Life |

|---|---|---|---|

| Auto Degree: | Fully Automatic | Material: | Machine |

| Type: | Stone Product Line, Artificial Stone Product Line | Usage: | Construction |

| Highlight: | Concrete Dosing Machine 12.7KW,200*200mm Artificial Stone Production Line,800m2/Day Wet Concrete Dosing Machine |

||

Product Description

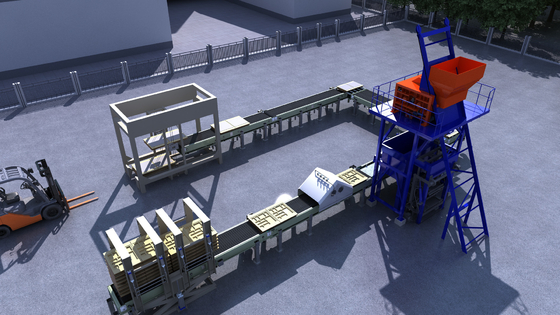

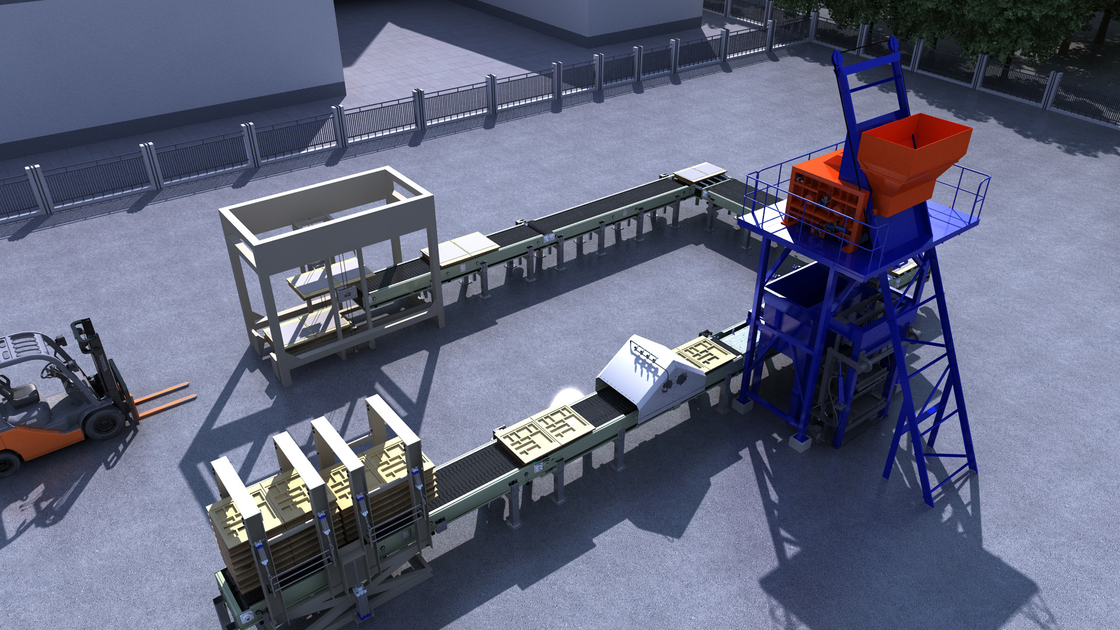

Concrete stone production line cement artificial stone production line with nice price

Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .Also,this machine can feed concrete automatically,and can fix the accurate concrete feeding by a pneumatic controller,can vibration automatically,can transport molds automatically,it is the better choice compare with the vibration table only both cost and efficiency.

Product Details:

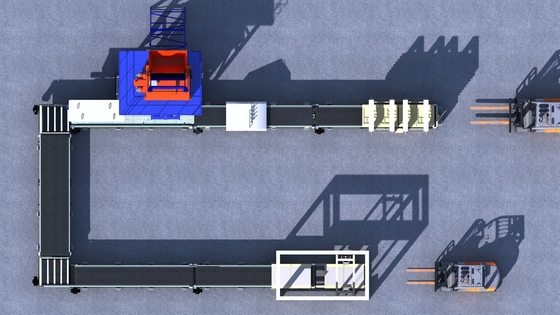

1. More efficient production, can achieve 800M2 Per day (8hrs) •

2. Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3. Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 |

Chain drived;Auto feeding,auto vibration |

8000*1100*1600 | 4.05 | 600-800 | 1500 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

1. Forklift

The forklift used to lift the empty molds pallet to the unloading machine ,and lift concrete filled molds pallet to the drying area/room.

2. Auto unloading machine

Release the molds pallet one by one on the transportation belt.adopt the pneumatic driving technology,compressor required to supply the air to the unloading machine.Frequency motor driving,stacking speed adjustable .

3. Auto Spray Machine

It has 3 function:

1> Dust remove from the mold surface

2> Color Painting to beautify the artificial stone ,improve the efficiency & labor numbers.

3> Spray the mold oil to achieve better mold release .

Working process:When the molds arrive the position,first two spray gun start working to paint the air to move the dust away ,the middle gun start paint the spot color when mold arrive its area,the the last two spray gun do the full color painting ,all will be controlled by the sensor and cabinet computer.and all data can be adjusted before production start.

4. Auto Concrete forced Mixer

Concrete mixer,mix the raw material with confirmed water quantity,and with a stable mixing time.to ensure the concrete will be evenly enough to inform the good quality artificial stone/paving tiles.

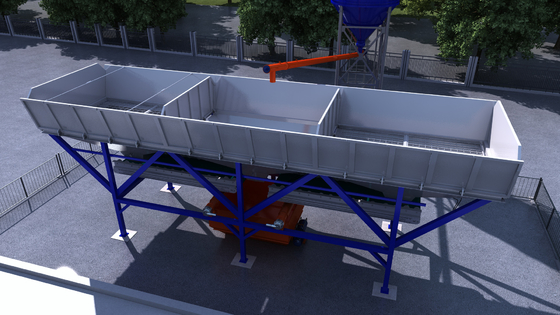

Auto Dosing Machine

It include the mixing hopper,concrete doser with pneumatic control and storage silo.

The bright spot:

1. concrete dosing can be calculated kilograms,not by time;thus to keep the dosing in a more accurate way.

2. Pneumatic door switching design,not wasting any more concrete for each dosing.

3. Adopt the storage silo for saving the concrete from each dosing,can save up to 75kg each time.

4. It has vibration function assembled with the dosing part,after dosing the concrete on the molds then will start vibration .

5. Digital screen controller,with all dosing weight available by only setting up the button ,it is fully automatic mode.

6. Save 6-8 labors for the factory,and reduce the working strength of the labors.

Adopt the frequency motor,all size of raw material will not stuck at the mixing & dosing process.make sure machine parts will long lasting use and power saving.

![]()

![]()

![]()

![]()

Our service:

We have different sales packages according to customer requirements. Since each part of the production line is separate and separate, customers can purchase urgently needed parts, or purchase this complete production line in different steps to meet customer needs and more Higher and more cost-effective way.

![]()

Application:

Also we have many kinds of designs silicon mould for make artificial stone.The silicon moulds are very durable.Each mould can be used 2000 times at least.

The molds standard dimension is 560X560X45mm, weight 7.5kg one piece.

Artificial Stone has become an appreciated artwork to some extent. Types of brick face for natural-like series are imitated slad, imitated sandstone, imitated serpeggiante, etc.

![]()

![]()

![]()

![]()

1. Can you make custom designed products?

Yes, we can according to customer requirements, such as shape, size, color, pattern and other details of the product to make.

2. How could I know the price of the item?

If you want to know our normal products, you just tell us the item number and your information, I'll give you the best price

Our Certificate:

![]()