Automatic Concrete Paver Making Machine Wet Dosing 12.7 KW

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stones Feeding Machine Line Production | Feature: | Automatic |

|---|---|---|---|

| Size: | 7000*1000*1800mm | Capacity: | 800-1000m2 |

| Power: | 12.7 KW | Type: | Artificial Stone Product Line |

| Highlight: | Wet Dosing Concrete Paver Making Machine,1000m2 Concrete Paver Making Machine,12.7 KW Concrete Paver Dosing Machine |

||

Product Description

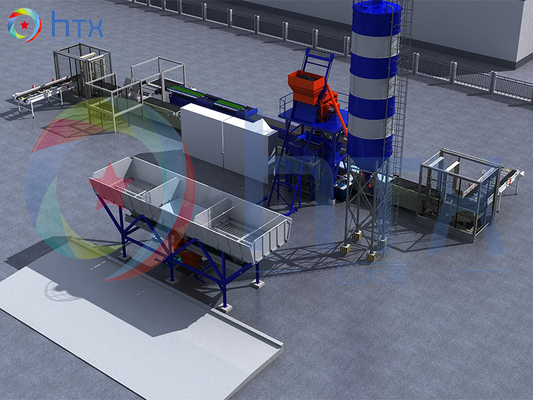

Concrete Paver Making Production Line Automatic Concrete Wet Dosing Machine

Product Description

Concrete precast machine line Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

The cultural stone production line relates to the technical field of artificial stone production, and discloses an artificial cultural stone mold turning device, comprising a first conveying platform and a second conveying platform arranged in parallel, and a turning frame is arranged between the first conveying platform and the second conveying platform, A clamping mechanism is arranged in the overturning frame, the end of the overturning frame is provided with a holding mechanism corresponding to the clamping mechanism, and the second conveying platform includes a material receiving and conveying mechanism corresponding to the overturning frame and the clamping mechanism. The mold is turned over from one conveying platform to another conveying platform through the turning frame, so as to realize the turning of the mold and prepare for the subsequent demoulding. The structure is simple, the turning efficiency is high, and it can be effectively combined with the subsequent demoulding process. , greatly improving the production efficiency, strong practicability and good use effect.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

![]()