Automatic Concrete Wet Casting Doser Pallet Transfer Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Artificial Stone Concrete Dosing Machine Wet Casting Doser Machine. |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Product Name: | Automatic Concrete Cement Interlocking Hollow Brick Making Machine | Weight: | 2000KG |

|---|---|---|---|

| Style: | Full Auto | Application: | Interior And Exterior |

| After Warranty Service: | Online And Video Technical Support | Type: | Artificial Stone Product Line |

| Highlight: | Wet Doser Pallet Transfer Machine,Casting Concrete Doser Machine,Automatic Wet Concrete Dosing System |

||

Product Description

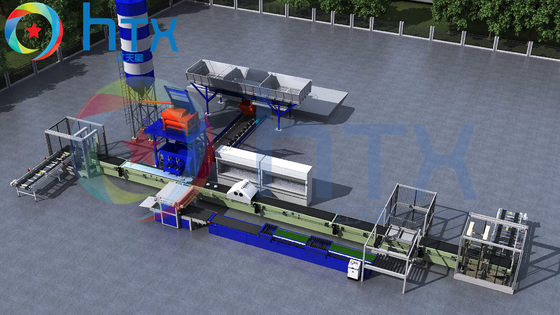

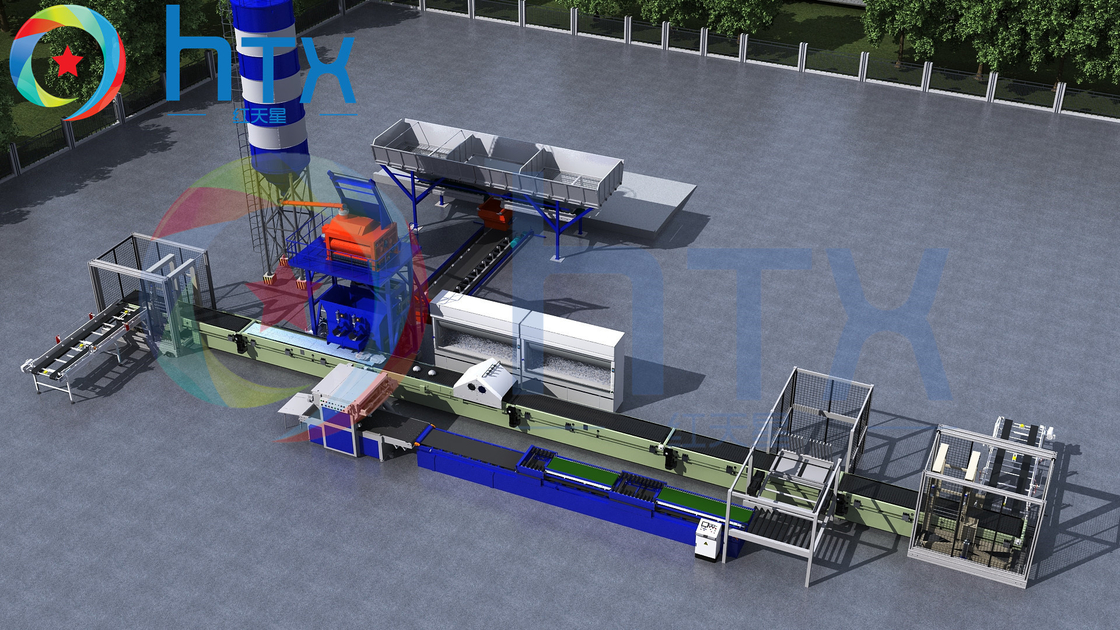

Automatic casting concrete wet doser Pallet transfer machine wet casting doser machine line

The artificial stone production line main parts are cement silo, batching machine, auto wet concrete dosing part, auto concrete fixed mixer, auto unloading and stacking machine, auto spary machine(used for add color for veneer stone), auto demolding machine, finished culture stone drying, and so on. In a whole word, from material to finished artificial stone package all full auto.

With the full auto artificial stone production line, the veneer stone manufacturer can save a lot of labor cost and can Increase productivity. More over, it can achieve collect dust in the workplace to protect environment, and also can demold automatically, this is a new progress during veneer stone production.

Culture stone also called Veneer stone or artificial stone. Used for external or interior wall decoration. Very popular in the world and have good market. In order to help the manufacturer make culture stone easily, our company Henan HTX Group designed full auto veneer stone production line.

Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .

oncrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Artificial Stone has become an appreciated artwork to some extent. Types of brick face for natural-like series are imitated slad, imitated sandstone, imitated serpeggiante, etc.

![]()

![]()

Our Certificate:

![]()

Want to Know more details about this product