Automatic Artificial Stone Production Line With Demoulding Wet Cast Concrete Doser

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Artificial Stone Concrete Dosing Machine Wet Casting Doser Machine. |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Product Name: | Automatic Concrete Cement Interlocking Hollow Brick Making Machine | Dimension(L*W*H): | 12000*1800* 2100 |

|---|---|---|---|

| Key Selling Points: | High Productivity | Feature: | Automatic |

| Keywords: | Automatic Concrete Casting Wet Doser Machine | Function: | Producing Artificial Stone |

| Highlight: | Wet Cast Concrete Doser Machine,Automatic Artificial Stone Concrete Doser,Demoulding Artificial Stone Production Line |

||

Product Description

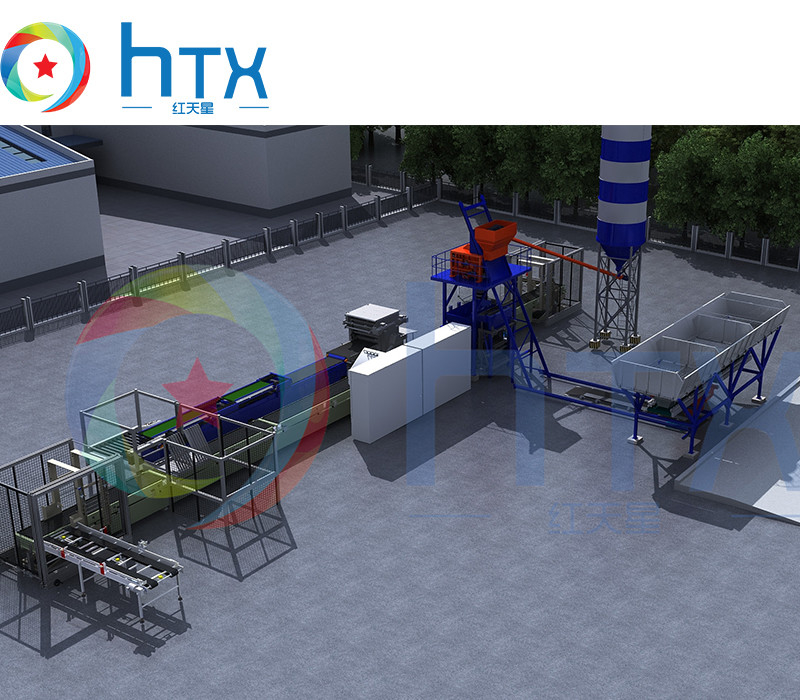

Fully Automatic Wet Cast Concrete Doser Machinery Artificial Stone Production Line With Demoulding

With the full auto artificial stone production line, the veneer stone manufacturer can save a lot of labor cost and can Increase productivity. More over, it can achieve collect dust in the workplace to protect environment, and also can demold automatically, this is a new progress during veneer stone production.

Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .

The full auto production line include cement silo, batching machine, and forced auto mixer. The cement silo need equipped with a screw feeder. To delivery cement into mixer. The batching machine have two or three hoppers. And have weighted function at bottom of each hopper. All the three machines need a PLC controller to control each function.

oncrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

We use 100% natural stones to create our natural stone veneer,which ensures that our molds will reproduce 100% natural stone textures. Artificial stone, we provide one stop service, including molds, equipped with semi auto and full auto production lines, complete color ingredient and training, and special stone molds customization.

Our Certificate:

![]()