Wet Cast Concrete Machinery Paving Block Artificial Stone Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Wet Cast Concrete Machinery | Type: | Artificial Stone Product Line |

|---|---|---|---|

| Advantage: | Multi Function Wet Casting Doser Machine Production Line | Size: | 7000*1000*1800 |

| Material: | Steel | Application: | Interior And Exterior |

| Highlight: | Steel Wet Cast Concrete Machinery,Paving Block Artificial Stone Production Line,Artificial Stone Automatic Dosing System |

||

Product Description

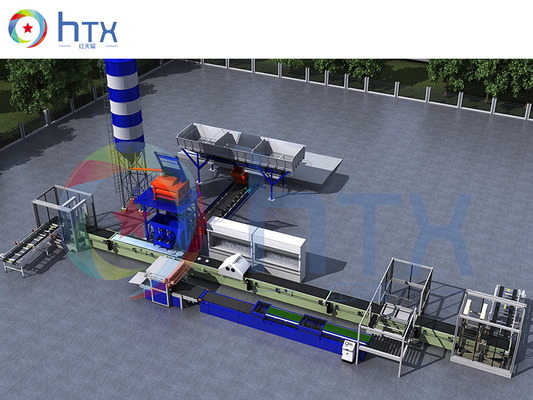

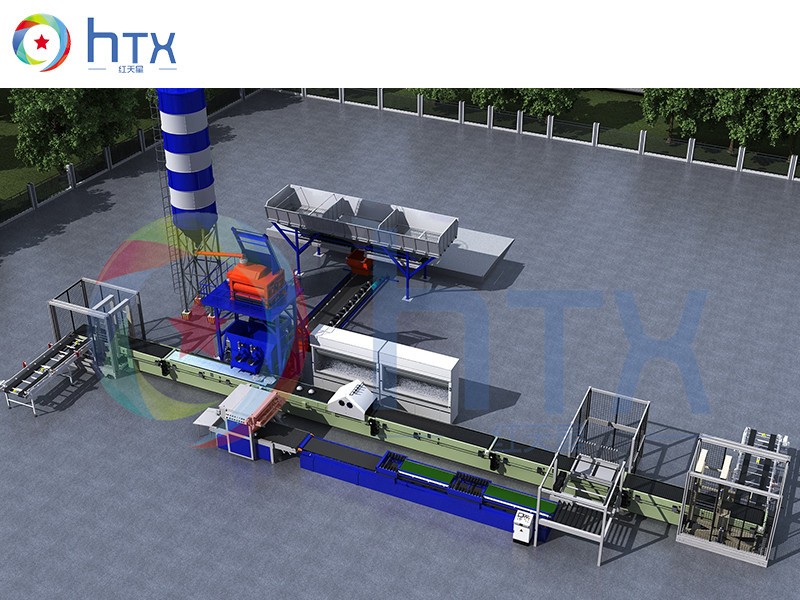

Wet Cast Concrete Machinery Paving Block Artificial Stone Production Line

Product Description

As a factory specializing in the production of paver tile molds, we also provide customers with a variety of production line solutions for the production process of finished paver tiles. One of the solutions is single dosing production line + concrete mixer + PLC control cabinet.

1.Single Dosing machine: Size: 9000*1000*2000mm, 10.7kw, the machine is controlled by a time relay, timing vibration, timing feeding, weighing control;

2. Automatic concrete mixer: size: 2200*1800*2000mm, 25.6kw, the machine is automatic water supply, automatic mixing, automatic unloading;

3.Control cabinet PLC: Both 12v&220v, size: 600*800*50mm; touch screen, weighing adjustment and time control;

This equipment is an upgraded version of the above blue equipment.

1. The feeding method is adjusted from horizontal unloading to bottom-up pumping and feeding. The feeding amount is more stable, and there will be no leakage or uneven feeding.

2. A weighing system is added, and there is a weighing device under the discharge opening,which can weigh 5-25 kg of concrete, making the discharge volume more accurate.

3. A digital display PLC control system is added, which is easy to operate and more intelligent.

Applications

Concrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

![]()

Certificate

![]()