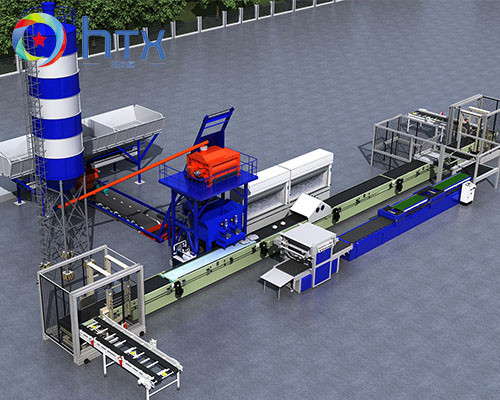

Automatic Concrete Fence Panel Production Line Artificial Stone Manufacturing Machine

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Operation: | Automatic | Type: | Wet Cast Machinery |

|---|---|---|---|

| Capacity: | 1000-1200m2 | Size: | 7000*1000*1800mm |

| Product Name: | Multi Function Wet Casting Doser Machine Production Line | Function: | Producing Artificial Stone |

| Highlight: | Multi Function Artificial Stone Manufacturing Machine,Automatic Concrete Fence Panel Production Line,Wet Cast Fence Panel Production Line |

||

Product Description

Automatic offers both standard and custom Wet Cast solutions adaptable to a wide range of clients, from the young, limited in production volume to the more experienced and high production volume manufacturers. In other words, our Wet Cast production components could easily fit within an already existing manual, semi-automatic or fully-automatic production line while our turn-key projects provide a made-to-order solution to your specific needs. Also, since our lines could be as modular and versatile as they are dedicated, manufacturing a full range of different product types such as masonry, slabs, walls, steps, veneers, edges or caps of different shapes and sizes on a single line is as easy and efficient as producing a single product category.

| Name | Model | Specification |

Size(mm) |

Power(Kw) |

Capacity(m2/day) |

Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

![]()

Our Wet Cast lines enable you to:

- Select the stations you require and customize your production lines based on your current needs while also keeping future productivity in mind.

- Maximize the output of each line independently of the others and provide for partial function of your facility in the event of a breakdown or shortage of a raw material; for example, your demolding line can remain active even if your pouring line is shut down.

- Configure flexible layout based on facility requirements and target production flow.

- Consider fast, customized expansion at low cost of a semi-automatic line to achieve complete automation.

Applications:

Support and Services:

We provide technical and after sales support and services for our Wet Cast Machinery products. We are committed to delivering the highest level of support and services for our customers and value their feedback to ensure our products meet the highest standards of quality and reliability.

Our technical support and service offerings include:

- On-site installation and commissioning

- Regular maintenance and preventive care

- Troubleshooting and diagnosis

- Training and education

- Remote monitoring and diagnostics

- Replacement parts and components

- Product upgrades and enhancements

We strive to provide our customers with the best possible service and support experience. We are committed to responding quickly to customer inquiries and resolving any issues in a timely manner.