Manuel Brick Machine-Simple And Small Brick Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

|

Detail Information |

|||

| Features: | Producing Artificial Stone | Auto Degree: | Fully Automatic |

|---|---|---|---|

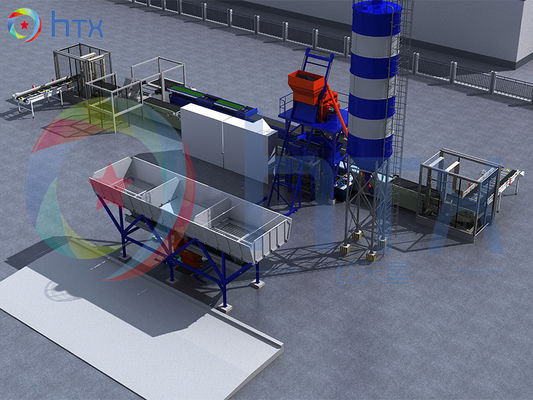

| Brick Type: | Concrete Dosing System | Dimension: | 8000mm X 2000mm X 2000mm |

| Raw Material: | Conrete | Model: | XYZ-100 |

| Feature: | High Productivity | Style: | Full Auto |

| Warranty: | 1 Year | Control System: | PLC |

| Material: | Steel | Application: | Precast Concrete Production |

| Voltage: | 220V | Weight: | 5000kg |

| Power Supply: | 380V/50Hz | ||

| Highlight: | Manuel Brick Making Machine,Small Brick Making Machine,Simple Brick Making Machine |

||

Product Description

A manual brick machine, also known as a manual brick press or manual brick maker, is a simple mechanical device used to produce bricks manually. It is typically operated by hand and does not require any external power source.

![]()

![]()

1,Preparation: Prepare the required materials for brick production, including soil or clay (or a combination of both), sand, water, and any additional additives or stabilizers. The soil or clay should be properly mixed, free of large debris, and have the right moisture content for brickmaking.

2,Loading the Mixture: Place the prepared soil or clay mixture into the hopper or feeding chamber of the manual brick machine. It may have a lever or mechanism to control the flow of the mixture into the mold.

3,Compression: Press down on the lever or handle of the manual brick machine to apply pressure to the soil or clay mixture inside the mold. This compresses the mixture and forms it into the shape of the brick.

4,Ejection: Release the pressure on the lever or handle to allow the compressed brick to be ejected from the mold. The brick is then set aside to dry and cure, usually in a shaded area or under cover.

5,Repeat: Repeat the process of loading the mixture, applying pressure, and ejecting the brick for each subsequent brick.

![]()

![]()

Manual brick machines are often used in small-scale brickmaking operations, especially in areas where electricity or automated machinery is not readily available. They can be a cost-effective option for producing bricks for construction, provided that the proper techniques and materials are used.