Manual Paver Cement Brick Maker Machines Artificial Stones Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Factory Concrete Artificial Stone Production Line | Voltage: | 220V |

|---|---|---|---|

| Key Selling Points: | High Productivity | Capacity: | 800-1000m2 |

| Brick Type: | Concrete Dosing System | Weight: | 2000KG |

| Highlight: | Manual Paver Cement Brick Maker Machines,Artificial Stones Brick Maker Machines,Cement Brick Wet Cast Machinery |

||

Product Description

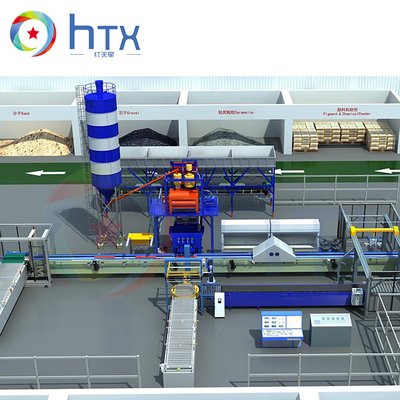

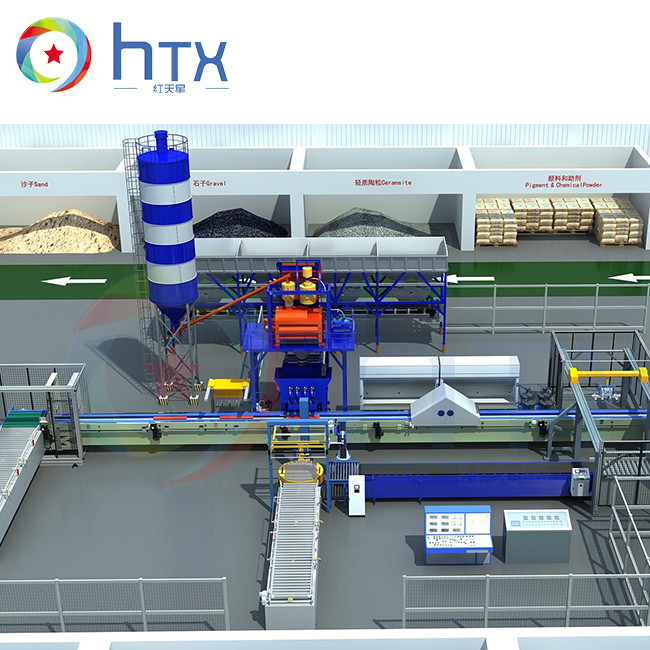

Manual Paver Cement Brick Maker Machines Artificial Stones Production Line

Product Description

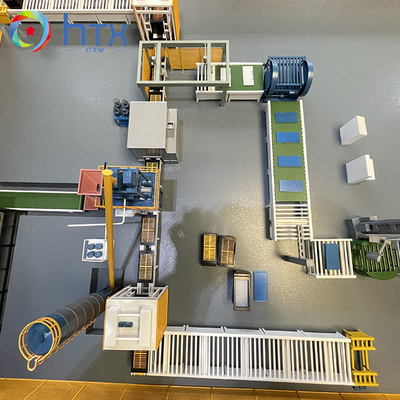

Wall panel production equipment is a specialized set of machines and equipment used to produce wall panels for construction and interior design applications. Wall panels are typically made from a variety of materials, such as concrete, wood, metal, and plastic, and can be used for aesthetic or functional purposes.Wall panel production equipment can vary based on the type of wall panel being produced and the materials used.

Wall panel production equipment can be highly automated, with computerized controls to ensure precision and consistency throughout the manufacturing process. The equipment can be designed to produce a range of wall panel types and sizes, and can be adjusted to meet specific customer requirements in terms of material selection, texture, and finish.

Overall, wall panel production equipment is an essential component of the construction and interior design industries, providing a versatile and cost-effective solution for creating durable and aesthetically pleasing wall panel products. The production line can be designed to be modular, allowing manufacturers to add or remove specific components as needed to meet changing market demands.

Applications

The feeding method is adjusted from horizontal unloading to bottom-up pumping and feeding. The feeding amount is more stable, and there will be no leakage or uneven feeding. A weighing system is added, and there is a weighing device under the discharge opening,which can weigh 5-25 kg of concrete, making the discharge volume more accurate.A digital display PLC control system is added, which is easy to operate and more intelligent.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

![]()

![]()

![]()

Certificate

![]()