PLC Control System Wet Cast Machinery Floor Tile Making Machine 220V

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Control System: | PLC | Material: | Steel |

|---|---|---|---|

| Operation: | Automatic | Voltage: | 220V |

| Weight: | Heavy | Motor: | High-Performance |

| Power: | High | ||

| Highlight: | PLC Floor Tile Making Machine 220V,Wet Cast Machinery High Speed,Floor Tile Wet Cast Concrete Machinery |

||

Product Description

Product Description:

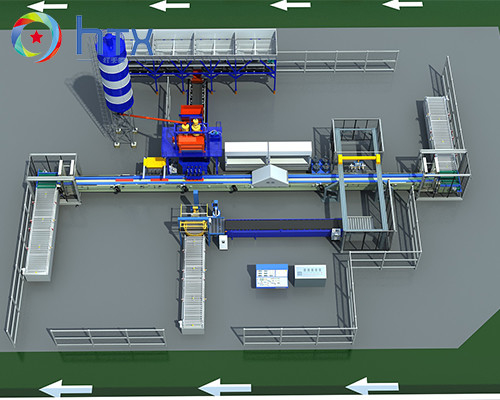

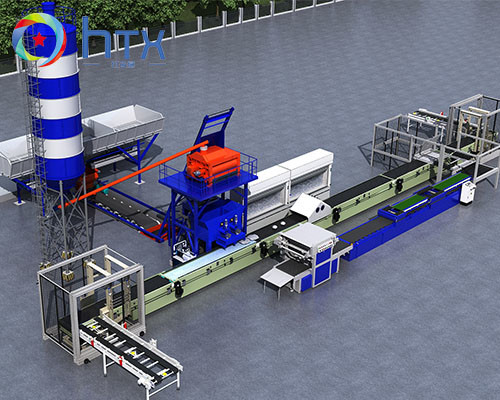

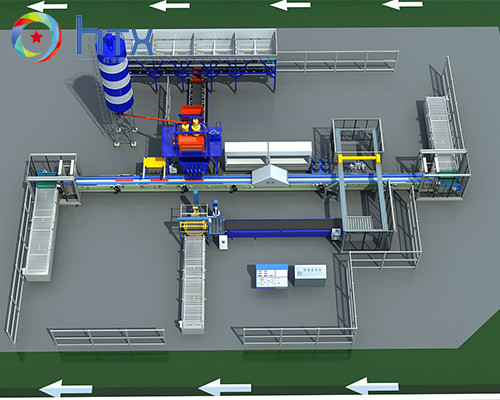

Wet Cast Machinery is an advanced and reliable veneer stone production line for making high-quality cultured stone. Its core component is a high-performance motor, which is made of steel material and features high speed and high accuracy. This machinery is designed to meet the needs of stone manufacturers and offers excellent performance in wet cast production. It is reliable, efficient, and cost-effective. With its high-performance motor and steel material, Wet Cast Machinery can provide superior performance and outstanding accuracy in stone production. It is easy to use and maintain, making it a great choice for stone manufacturers. It is also highly safe and durable, ensuring that it can withstand the rigors of stone production for a long time.

Features:

- Product Name: Wet Cast Machinery

- Maintenance: Low

- Durability: High

- Size: 7000*1000*1800mm

- Speed: High

- Power: High

- Automatic Wet Cast Dosing System

- Cultured Stone Making Machine

- Plastic Paver Production Line

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

![]()

Applications:

HTX wet cast machinery is a reliable solution for industrial production lines. Made with high-performance motor and durable steel material, it can guarantee high speed and low maintenance. The heavy weight of the machine makes it perfect for artificial stone and veneer stone production lines. With its superior strength and stability, the wet cast doser machine is your best choice for your production line.

Customization:

Brand Name: HTX

Place of Origin: HENAN

Durability: High

Control System: PLC

Power: High

Operation: Automatic

Voltage: 220V

Specialized in Production Line: Veneer Stone Production Line, 3D Wall Panel Production Line, 3D Wall Panel Production Line, 3D Wall Panel Production Line.

Support and Services:

At Wet Cast Machinery, we are passionate about providing the best possible customer service and technical support for our machinery.

Our highly experienced and knowledgeable team is available to answer any questions and provide guidance on installation, maintenance, and troubleshooting. We are committed to providing timely and accurate assistance, so you can get the most out of your Wet Cast Machinery.

We also provide a variety of services to keep your machinery running smoothly, including:

- Regular maintenance checks to ensure optimal performance

- Upgrades and modifications to keep up with industry standards

- Replacement parts for worn or damaged components

- On-site training to help you and your staff get the most out of your Wet Cast Machinery

At Wet Cast Machinery, we are dedicated to helping you get the most out of your machinery. If you have any questions or need assistance, please do not hesitate to contact us.

Packing and Shipping:

Wet Cast Machinery Packaging and Shipping:

We package the Wet Cast Machinery with special packaging materials such as bubble wrap, foam, cardboard, and other protective materials to ensure that the product reaches its destination in perfect condition. We then ship the product via air, sea, or ground transport, depending on the customer's needs.