Paving 3D Wall Concrete Production Line Artificial Stone Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Marble Stone Production Line | Type: | Artificial Stone Product Line |

|---|---|---|---|

| Color: | Blue | Brick Type: | Concrete Dosing System |

| Size: | 7000*1000*1800 | Auto Degree: | Fully Automatic |

| Highlight: | Concrete Dosing System Paving Stone Machine,Paving 3D Wall Concrete Production Line,Flagstone Concrete Production Line |

||

Product Description

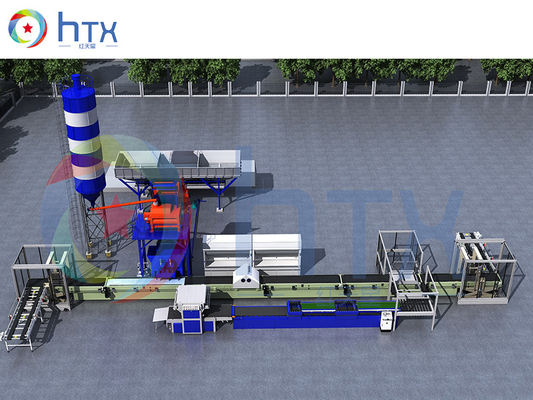

Paving Artificial Stone Artificial Stone Production Line 3D Wall Concrete Production Line

Product Description:

Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .The mold is turned over from one conveying platform to another conveying platform through the turning frame, so as to realize the turning of the mold and prepare for the subsequent demoulding.Fully automatic production line equipment for customers to save labor costs, reduce labor, and achieve automation and high-efficiency production. According to the driving method, it can be motor-driven, pneumatic, or hydraulically-driven, pneumatic and electric. According to the size of the concrete mold, they design the length and width of the production line, and also the size and quantity of the mold position. According to the concrete mold size, weight, and customer's production requirements, they design the feeding part, which can be two blanking ports, four blanking ports, or 5 blanking ports, to meet the production quantities of customers with various sizes of products.

Specification:

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

Finished Products

![]()

![]()

![]()

![]()

![]()

![]()

Certificate

![]()