Wall Panel Concrete Dosing Machine Artificial Stone Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30 work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Wall Panel Production Machine | Feature: | Easy To Operate |

|---|---|---|---|

| Power: | 12.7 KW | Key Selling Points: | High Productivity |

| Material: | Steel | ||

| Highlight: | Wall Panel Concrete Dosing Machine,Artificial Concrete Dosing Machine,Flagstone Concrete Wall Panel Machine |

||

Product Description

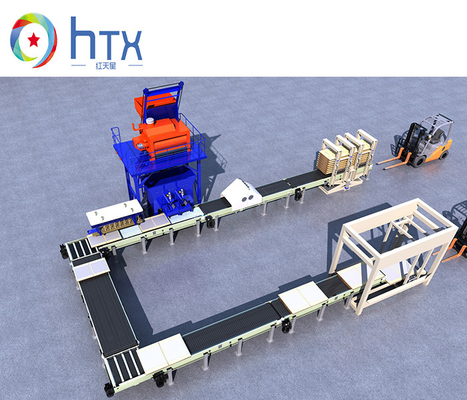

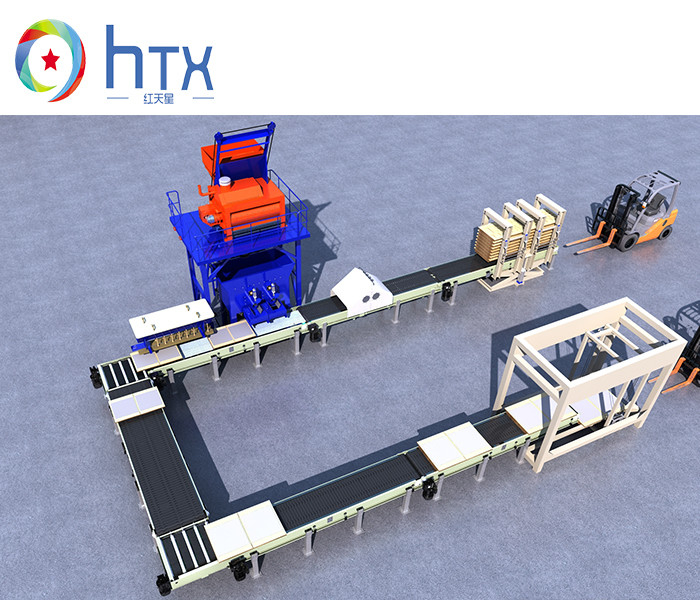

Wall Panel Production Machine Concrete Dosing Machine Artificial Stone Production Line

Product Description:

The artificial stone production line main parts are cement silo, batching machine, auto wet concrete dosing part, auto concrete fixed mixer, auto unloading and stacking machine, auto spary machine(used for add color for veneer stone), auto demolding machine, finished culture stone drying, and so on. In a whole word, from material to finished artificial stone package all full auto. Stone concrete Innovative production line for decorative stones, designed to handle the Changing needs of any producer. Schiasio-Spil offer both atandard and customized solutions that can be adapted to a wide range of products. Manual semi-automatic or fulll-automatic configurations are available according to the requirments of the client. A full range of different wet-cast products can be produced such as slabs, masonry , steps, edges or veneers of different shapes and sizes on a single line.

Stone concrete can be integrated into existing production lines and works with different tyyes of molds like for instance polyurethane, silicone, Abs and steel . The modular stystem of entire Stoneconcrete line allows various combinations and production capacity , depending on the type and quantity of concrete dosing devices and vibration stations.

Specification:

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

Finished Products

![]()

![]()

![]()

FAQ:

1. Can you make custom designed products?

Yes, we can according to customer requirements, such as shape, size, color, pattern and other details of the product to make.

2. How could I know the price of the item?

If you want to know our normal products, you just tell us the item number and your information, I'll give you the best price

If you have individual design requirements, please tell us the following information so that we can offer the price immediately.

1) Product model and measurements (you better have drawings, samples or photos).

2) The expected delivery time.

3) Your contact details information.

3. What is the MOQ ?

Under normal circumstances, there is no limited to MOQ. It is subject to our esteemed customers. More quantities, the price is more better.

4. How could I get the samples?

For the first cooperation, we ask the samples fare + shipping cost, and we will give back the cost after the customer place the order.

For the regular cooperation customers,we offer free

sample fare+shipping cost .

5. How can I install these samples?

We will send you the installation procedures including the video or picture for you reference. You can also call our hot line.