Palletising Stone Production Line Precast Concrete Dosing System

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stone Automatic Production Line | Power: | 37.6KW |

|---|---|---|---|

| Dimension(L*W*H): | 1200*1800* 2100 | Key Selling Points: | High Productivity |

| Feature: | Automatic | Capacity: | 800-1000m2 |

| Highlight: | Precast Concrete Stone Production Line,Palletising Stone Production Line,Flagstone Concrete Dosing System |

||

Product Description

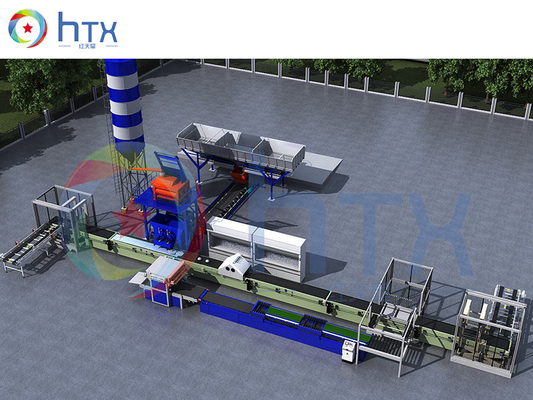

Concrete Dosing System Palletising Pre Cast Concrete Stone Production Line

Product Description:

wet casting doser machine Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.The cement silo tank is equipped with a material level system, which can display the position and amount of the material, and the hole-breaking device can relieve the solidity caused by the material deposition for too long.At present, the more common types of cement silos on the market include horizontal cement silos, vertical cement silos, and assembled cement silos (also called sliced cement silos).

1. The horizontal cement silo is square, the bottom is supported by several legs, the discharge cone is a square cone, the silo is welded by a frame composed of corrugated cardboard and profiles, and the overall height is low.

The production workshop of the horizontal cement silo is a complete set of production, and there is no basic installation on site. The horizontal cement silo is mainly used for mobile batching plants and concrete batching plants.

2. The vertical cement silo is a cylindrical structure, and the bottom is supported by four round tube legs. The entire silo is welded with steel structure, and the top is equipped with a dust collector and a pressure relief valve.

Vertical cement silo is suitable for bulk cement and dry fly ash. It has the characteristics of rainproof, moistureproof and easy to use. Usually used as a supporting product for concrete batching plants (construction).

3. Prefabricated cement silo, also known as sheet cement silo, is made into thin sheets during production, which is convenient for transportation and used after assembly, especially suitable for export.

The installation of the flake cement silo is more complicated and the cost is higher, but the transportation of the flake cement silo is more convenient.

Specification:

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

Finished Products

![]()

![]()

![]()

![]()